In hospitals the concern grows: antibiotic-resistant agents are spreading and can be the cause for dangerous infections. The increasingly fast pace of the transitions between patients is amplifying this problem. But there is good news: Stiegelmeyer and Belimed are using their strong competences in the area of hospital hygiene to build on them together.

Frequency of hospital-acquired infections

A worldwide challenge

In hospitals the concern grows: antibiotic-resistant agents are spreading and can be the cause for dangerous infections. The increasingly fast pace of the transitions between patients is amplifying this problem. But there is good news: Stiegelmeyer and Belimed are using their strong competences in the area of hospital hygiene to build on them together..

Data source: World Health Organisation, 2011, Report on the Burden of Endemic Health Care-Associated Infection Worldwide

An invisible opponent

Much pollution on hospital beds can be seen at first glance and be cleaned on the surface rather easily. A much stronger opponent is the invisible contamination with germs and bacteria.

This problem can be solved with the automatic reprocessing of the beds. Stiegelmeyer and Belimed offer optimum products for this.

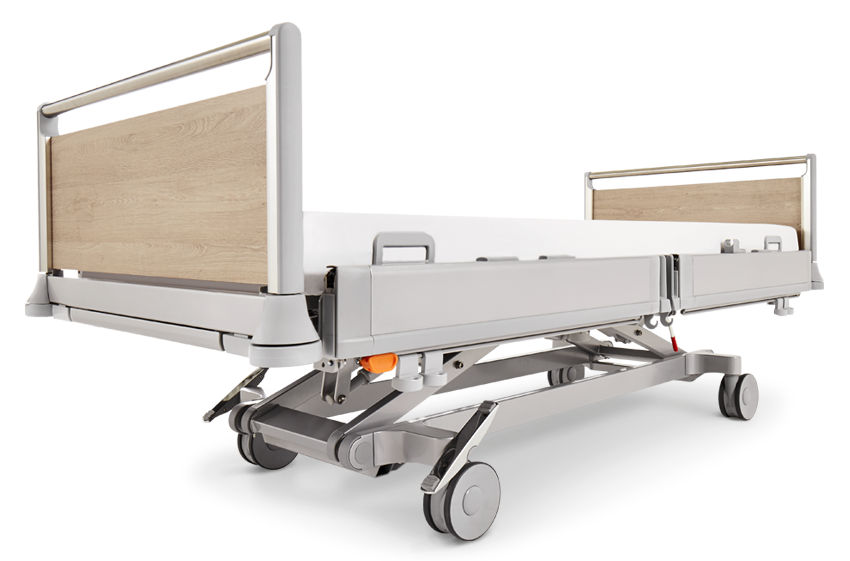

Puro –

the mashine washable hospital bed

The hospital bed Puro is setting new standards for hygiene. It offers special advantages for automated reprocessing:

- large-format design and curved shapes

- cables integrated into the bed frame

- cavity-sealed frame structure

- exclusive gasket seal for drive components according to IPX6W

- simple and quick activation of a pre-programmed washing position with only one touch

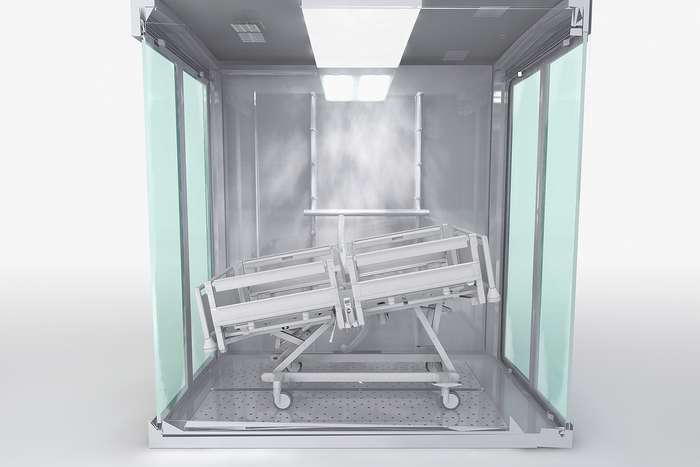

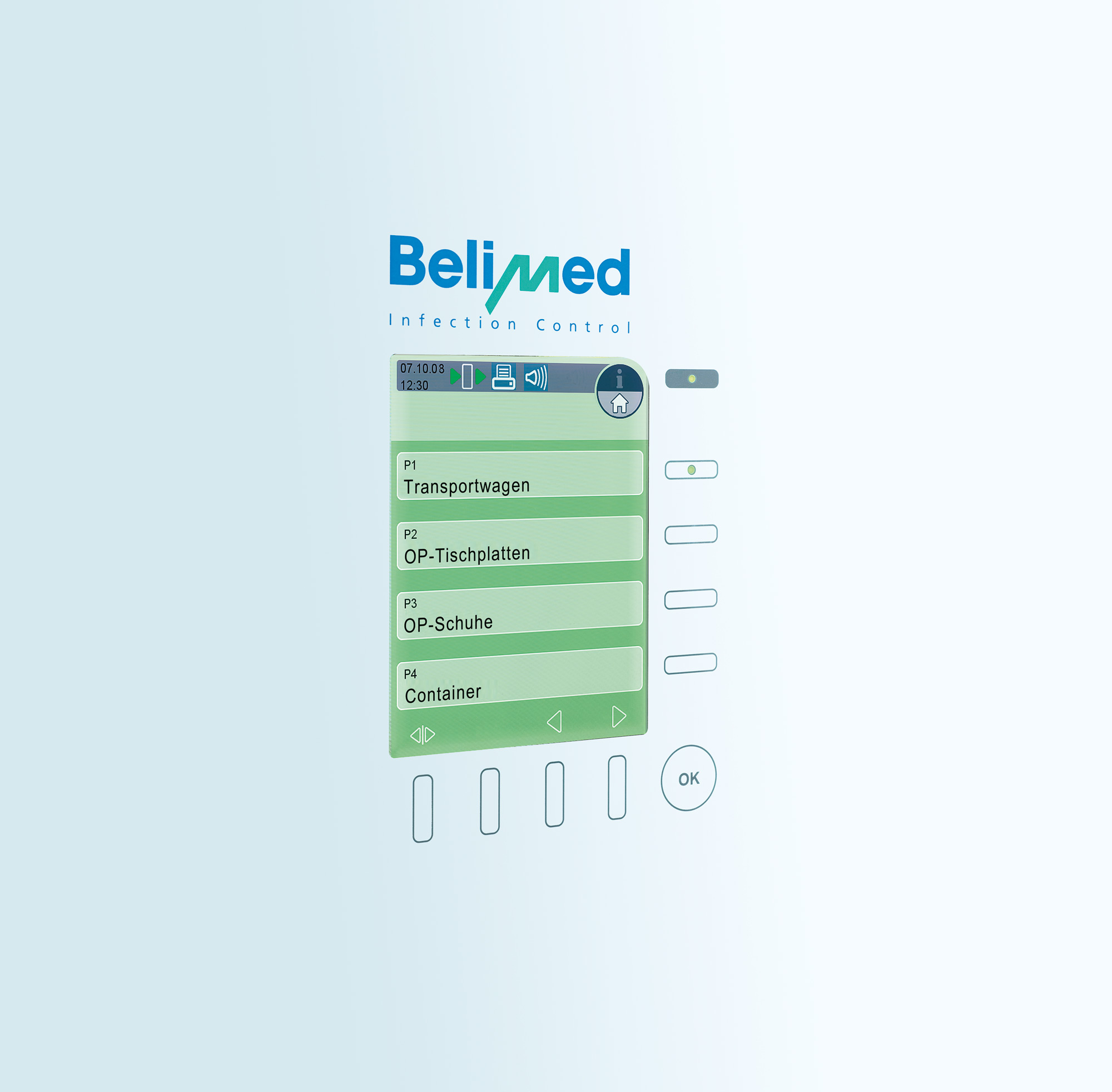

Cart washer CS 750 –

hygiene according to newest standards

The cart washer CS 750 from Belimed is raising the tone regarding the quality of bed reprocessing.

The washer

- meets the newest guidelines of the “Working Group for Bedframe and Cart Decontamination Systems” as well as norm DIN 58955

- does not use more than 16-30 litres fresh water per cycle

- offers open view of the washing process with its glass doors and chamber lighting

- is available in 3 different chamber lengths and 2 chamber widths

The course

of automatic reprocessing

The customers’ profit

Stiegelmeyer and Belimed combine 80 years of experience in the field of automatic bed reprocessing. Both companies now use this in order to perfectly harmonise their beds and cart washers.

Customers will profit due to

- a consistently high quality of the reprocessing outcome

- a more efficient workflow

- the reduction of overall operational costs

- the elimination of physically challenging actions during manual reprocessing